Proven capabilities across the entire engine and platform.

CPP has been purpose-built to be the growth partner of choice for complex castings. We are one of the few suppliers with proven capabilities across aero-engine, airframe, and industrial gas turbine platforms—ranging from the most complex multi-wall single crystal airfoils to large structural components. Our expertise spans both investment casting and sand casting and includes the full range of titanium-, Ni- and Co-based superalloys, steels, magnesium, aluminum, and other specialty alloys.

Airfoils.

CPP is the fastest-growing airfoils partner in our industry, specializing in cutting-edge casting technology for blades, vanes, and shrouds. Our capabilities include equiaxed, directionally solidified, and multi-wall single crystal airfoils for aerospace applications and a wide variety of IGT components, including the largest directionally solidified IGT blades.

Structural investment castings.

CPP specializes in titanium-, steel- and nickel-based superalloy investment structural castings, offering specialized capabilities for producing highly complex, thin-walled and large-scale components. As one of the few suppliers with the technical expertise to produce these components and alloys at scale, our capabilities enable us to deliver castings to furnish both engine and airframe applications.

Structural sand castings.

CPP leads the market in advanced structural sand castings, specializing in highly complex aluminum, magnesium, and steel castings for a wide variety of aerospace and defense applications. Our castings equip both commercial and military platforms, ranging from structural and engine components to helicopter, missile, fighter, and naval applications.

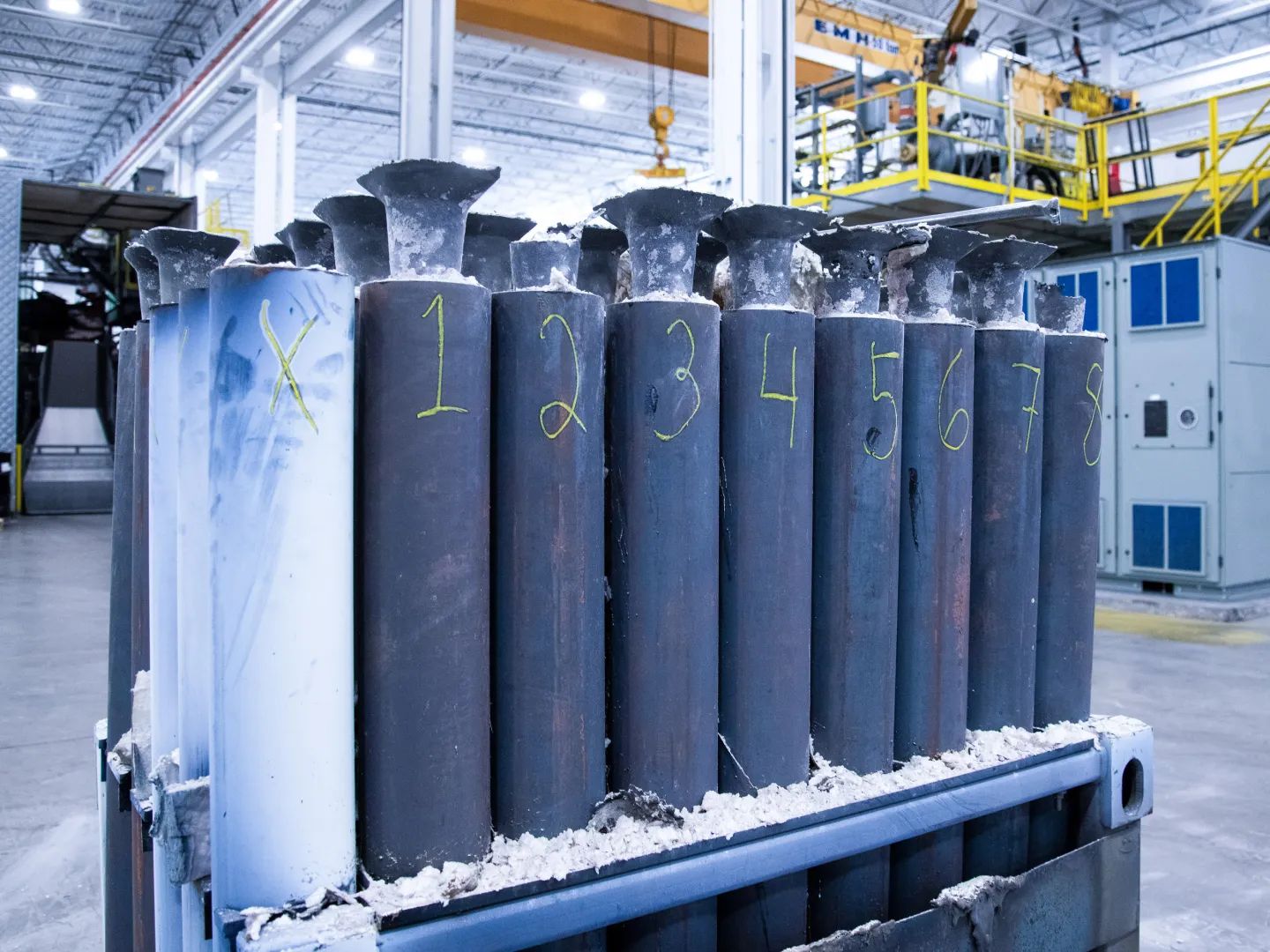

Metals.

Built to support the growing needs of CPP’s operations, our vertically integrated master melt facilities in New York and Oregon ensure a stable and consistent supply of vacuum-melt alloys to our casting sites. With an advanced approach to process control and precise alloy composition management, our facilities produce nickel, cobalt, and titanium superalloys engineered for optimal performance to support CPP’s related casting sites.

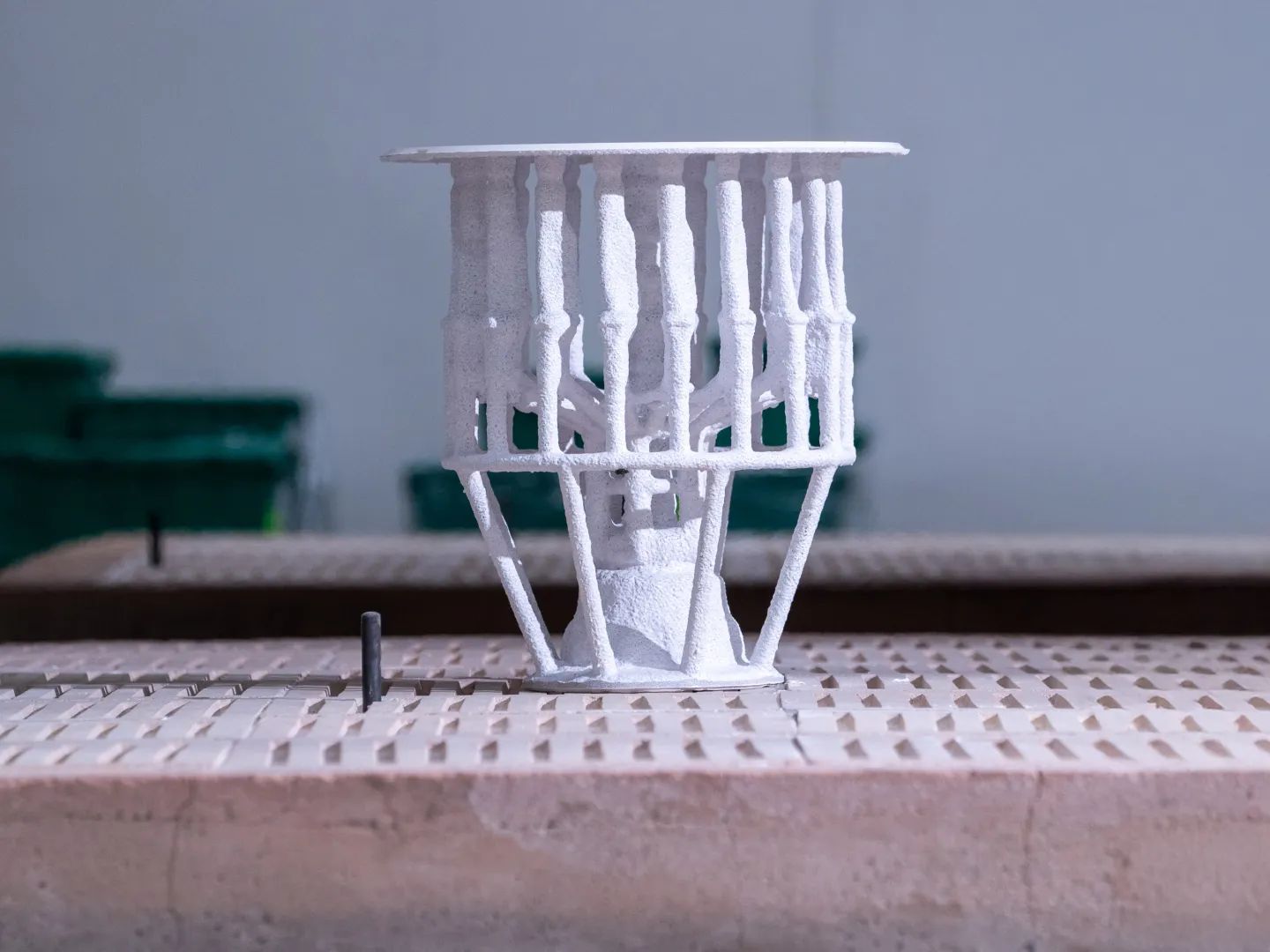

Core and wax technologies.

Delivering precise castings at scale requires advanced technologies at every stage of the process. Every investment casting begins as a wax pattern, and CPP’s AirPower Dynamics provides exceptionally accurate wax patterns and assemblies that drive exceptional results. For the most complex multi-wall airfoil geometries, CPP Poly6 utilizes unique and proprietary next-generation technology to produce the intricate cores required to form the cooling passageways within these castings. Together, the distinct capabilities of these sites enable CPP to meet the industry’s most-demanding requirements with creativity, precision, and consistency.

Help us shape the future.

Every CPP career comes with incredible growth potential and the satisfaction of knowing that you’re helping shape a better tomorrow for everyone—starting with yourself.